Performance above all

Hedson Academy

Completing the Hedson Academy gives you the knowledge and insight you need to support the end-customer in a professional and efficient way

Hedson on Youtube

Hedson YouTube-channel. See our videos, learn about our brands and discover the benefits of Hedson products

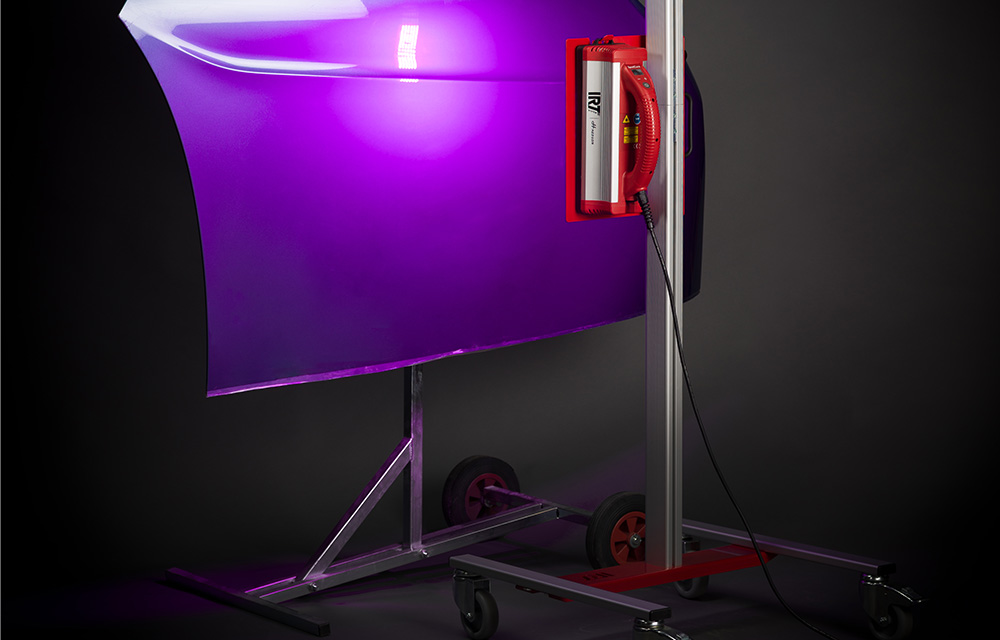

Body & Paintshops

Serve customers faster, better and more profitably with high performance workshop equipment from Hedson

Industrial Solutions

Infrared heating technology solutions for instant and precisely controlled heating to reduce production times, while lowering energy costs and saving the environment

WE OFFER YOU A FREE CONSULTATION!

We will help improve your efficiency & customize a solution

With the knowledge and experience within Hedson we will help optimize and improve the efficiency in your workshop. Hedson experts will quickly analyse, plan and visualize the optimal and wanted result in your workshop.

We will help finding the best solution for your shop!